Asil Civata

In 1999, Asil Bolt started to produce bolts with its double-blow machines. By integrating the hot-dip galvanizing plant in 2003, Asil directed all its investment and energy to the production of fasteners used in open areas.

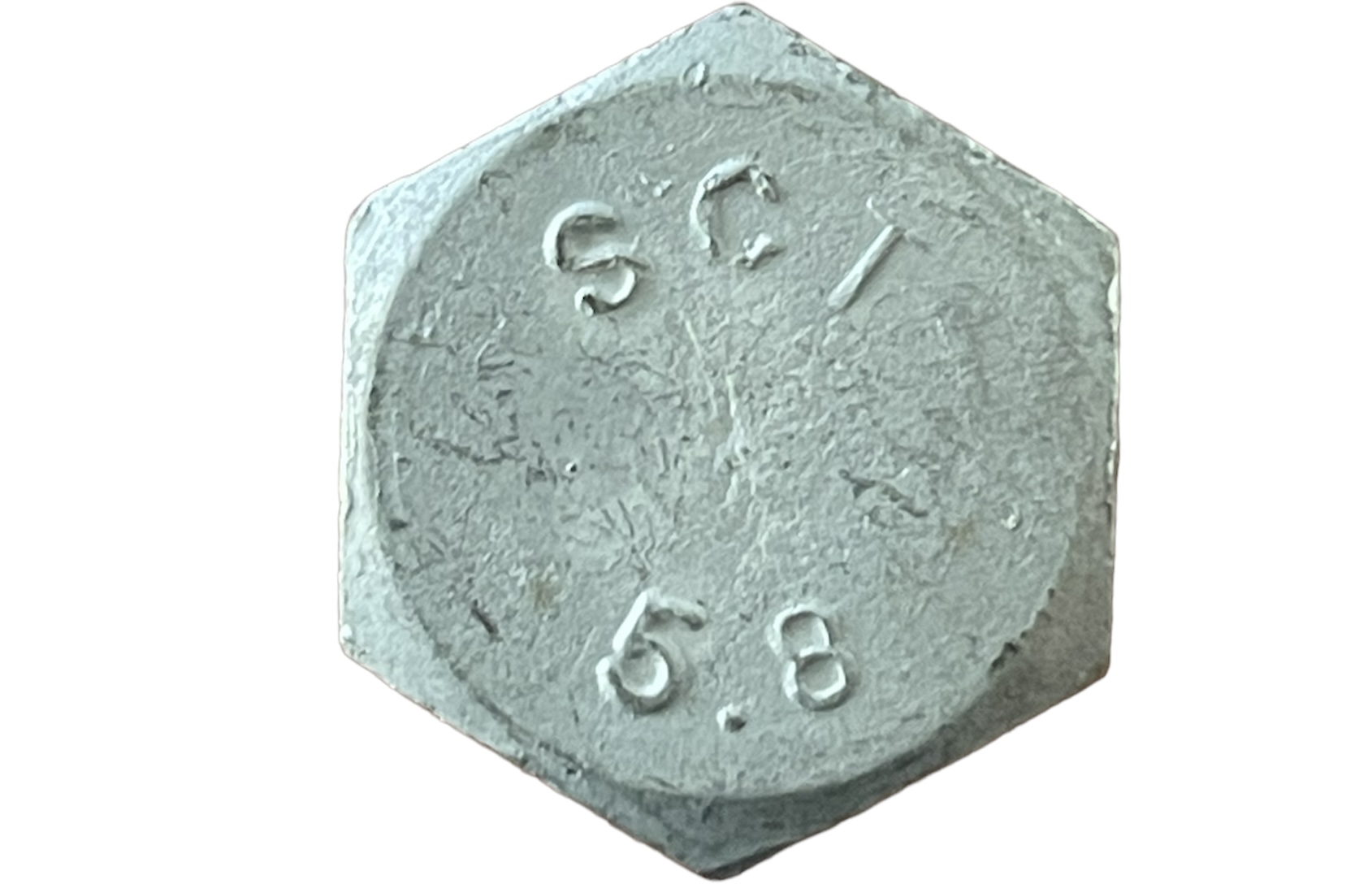

Asil Bolt produces hexagon head bolts with 4.8 5.8 6.8 8.8 grades in various standards between M8 and M24 size ranges by cold forging method for companies producing steel lattice towers.

Nuts and washers can also be assembled on the bolts. Asil Bolt produces all of the special head barrier bolts used in the highway safety barriers sector. Asil also manufactures sector-specific square and rectangular washers, bolts and various anchors. Flanged bolts and flanged nuts used in panels in field solar power plant projects are also in the product portfolio. In addition, Asil manufactures a wide range of fasteners in sizes from M6 to M52 for use in various steel structures such as railways, bridges and silos. Asil produces 10.9 quality non-hot-dip galvanized bolts, nuts and washers for use in areas such as the machinery industry and the automotive industry.

Sectors

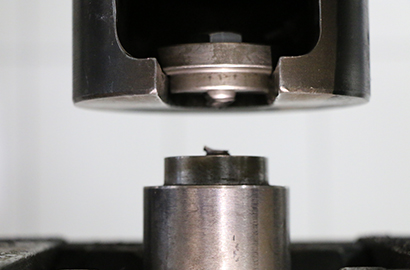

How We Produce?

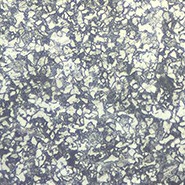

Hot Dip Galvanizing(HDG)

HOT DIP GALVANIZING(HDG) is one of the methods of protecting steel products from corrosion. It is the coating of the product by immersing it in a molten zinc bath. Zinc chemically bonds to the product surface and forms a hard layer. This coating formed on the surface prevents the oxidation of the steel by disconnecting it from the air. The hot dip galvanizing process is the best method to protect the steel, considering the reasonable price and long life.

Asil Bolt has a hot-dip galvanizing plant with an annual capacity of 24,000 tons of high-temperature coating. We now continue to work to put our low temperature coating facility into service in 2023. With this investment, hot-dip galvanized coating will be applied to 10.9 quality fasteners with diameters of M27 and above.